A entressafra no Nordeste, que geralmente ocorre entre novembro e março, é um período estratégico para as usinas de cana-de-açúcar e etanol realizarem a revisão e manutenção de seus equipamentos industriais. Com as operações paralisadas ou reduzidas, essa pausa oferece a oportunidade ideal para garantir que tudo esteja em perfeito estado para o próximo ciclo produtivo.

Realizar revisões durante a entressafra reduz riscos operacionais, evita falhas inesperadas durante a safra e prolonga a vida útil dos equipamentos. Além disso, essa prática reduz custos com manutenções emergenciais e melhora a eficiência operacional.

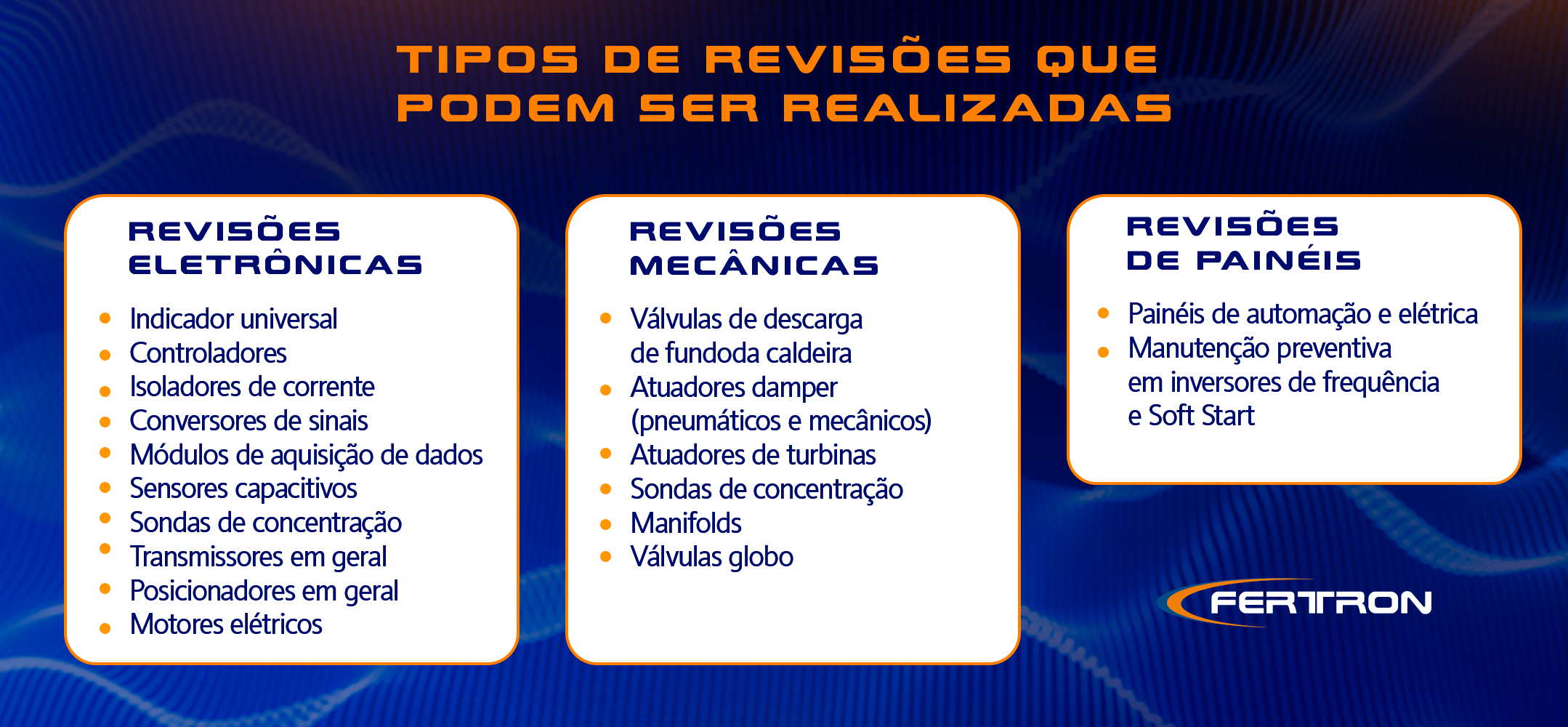

A Fertron é especialista em automação e elétrica industrial e está presente no Nordeste para oferecer suporte técnico completo às usinas durante a entressafra. Com filiais em Maceió (AL) e Recife (PB), a empresa disponibiliza peças, materiais de revisão e assistência especializada para manter sua operação no melhor desempenho.

Benefícios de Realizar a Revisão de Equipamentos na Entressafra

Realizar a manutenção preventiva na entressafra traz inúmeras vantagens para as usinas de cana e etanol. Entre os principais benefícios, destacam-se:

1. Evita falhas e paradas inesperadas na safra

Durante a safra, qualquer falha em equipamentos críticos pode comprometer toda a operação da usina, resultando em atrasos, desperdício de matéria-prima e redução na eficiência produtiva. Além do impacto direto na produção, falhas inesperadas podem gerar custos elevados com reparos emergenciais, mobilização de equipes e substituição de componentes às pressas.

Ao realizar uma revisão completa na entressafra, é possível identificar desgastes em peças, realizar ajustes e calibrações necessárias e substituir componentes que apresentam sinais de fadiga. Essa abordagem preventiva garante que todos os sistemas operem em condições ideais, evitando paradas indesejadas no momento mais crucial do ciclo produtivo.

2. Prolonga a vida útil dos equipamentos

Equipamentos industriais utilizados na produção de cana-de-açúcar e etanol operam sob condições extremas, como altas temperaturas, umidade e contato constante com resíduos de biomassa. Esses fatores aceleram o desgaste de componentes mecânicos e eletrônicos, tornando essencial a realização de manutenções regulares.

A revisão preventiva na entressafra permite identificar e corrigir desgastes antes que eles causem danos irreversíveis aos equipamentos. Isso evita que pequenas falhas evoluam para problemas maiores, que poderiam levar à necessidade de substituição prematura de máquinas e componentes.

3. Reduz custos com manutenções emergenciais

Os custos de uma manutenção emergencial durante a safra podem ser muito superiores aos de uma manutenção programada na entressafra. Quando um equipamento falha inesperadamente, a usina precisa agir rapidamente para corrigir o problema, o que pode envolver custos elevados com mão de obra extra, aquisição urgente de peças e até mesmo contratação de serviços especializados externos.

Além dos custos financeiros diretos, há um impacto significativo na produtividade da usina. Paradas inesperadas podem comprometer prazos de entrega, reduzir a eficiência dos processos e aumentar o desperdício de matéria-prima. Em alguns casos, a necessidade de reparos urgentes pode sobrecarregar equipes de manutenção, resultando em uma execução menos eficiente e aumentando o risco de erros.

Ao realizar revisões preventivas na entressafra, a usina minimiza esses riscos e mantém seus custos operacionais sob controle. Com um planejamento adequado, é possível adquirir peças com antecedência, realizar ajustes necessários sem comprometer a operação e garantir que todos os equipamentos estejam prontos para enfrentar a intensidade da safra sem contratempos.

Fertron: Sua Parceira para Revisão na Entressafra

A Fertron entende as necessidades específicas da indústria sucroalcooleira e oferece suporte especializado para garantir que seus equipamentos estejam prontos para a safra. Com presença no Nordeste, por meio de suas filiais em Maceió (AL) e Recife (PB), a empresa assegura atendimento ágil e soluções personalizadas para cada cliente.

Não deixe para última hora! A entressafra é o momento ideal para investir na manutenção e otimizar a eficiência dos seus equipamentos.

Entre em contato com a Fertron e garanta uma safra mais segura e produtiva.